I started making theses matched pair of V-Blocks in 2014 I had to ask Ken a friend who has a mini mill and tilting vice to finish them off for me. He did a great job for what I shall use them for. We did a DIG test and found a .004 discrepancy along a round bar, the bar may not be true so I will do it again on a known true bar or flat/square.

I used the 6x4 bandsaw to rough cut the V's, I machined the side slots on the Myford ML7 using my vertical slide mill. It just doesn't have enough travel for me to have done the final cuts. Yes i could have cut it in half and done it that way but the idea was to stretch my machine to its limit.

Marking out I use a Perm Marker and scribe.

The end was drilled centre of the two V's full length for form a relief area for the cutters and for square stock. I also drilled a pilot hole in each block this was to facilitate a 5/16W Cap bolt to secure them to T nuts but I decided not go ahead with that.

Below the set up using the vertical mill for the hold down slots to be cut.

Ken's work was having a clear out and he dropped this beaut universal vice around sadly its to big for the Myford and would get little use on the pedestal drill. Ken has it and used it to finish off the V-Blocks.

The vertical cuts being done on the 4x6 bandsaw removing the waste.

First one done I left enough to be machined hence the cut not being online.

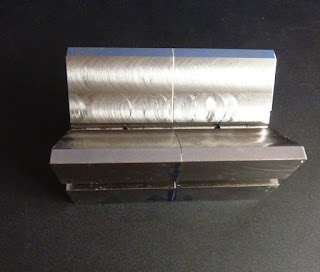

The finished V-Blocks below many thanks Ken first use not far away.

Blocks have been stamped to show matching ends.

Marking out I use a Perm Marker and scribe.

Marking out I use a Perm Marker and scribe.